Orthodontic brackets play a critical role in dental treatments, making their quality and safety paramount. High-quality orthodontic bracket manufacturers adhere to stringent material standards and testing protocols to ensure their products meet clinical demands. Rigorous testing methods, such as statistical analyses using SPSS and intention-to-treat evaluations, enhance the reliability of these products. These measures not only improve patient safety but also ensure consistent performance, ultimately leading to better treatment outcomes. By prioritizing compliance and innovation, manufacturers contribute significantly to advancing orthodontic care.

Key Takeaways

- Good orthodontic brackets help teeth treatment and keep patients safe. Pick brackets made by companies that follow strict rules.

- Brackets, like ceramic or metal, have different advantages. Choose based on your needs, money, and how they look.

- Strong testing makes sure brackets last through daily use. Find makers who test for strength and safety with the body.

- Following rules, like ANSI/ADA, ensures safety and trust. Use certified makers for your braces needs.

- Keeping teeth clean helps ceramic brackets last longer. Stay away from foods and drinks that can stain them.

Understanding Orthodontic Brackets

What Are Orthodontic Brackets?

Their role in aligning teeth and improving oral health.

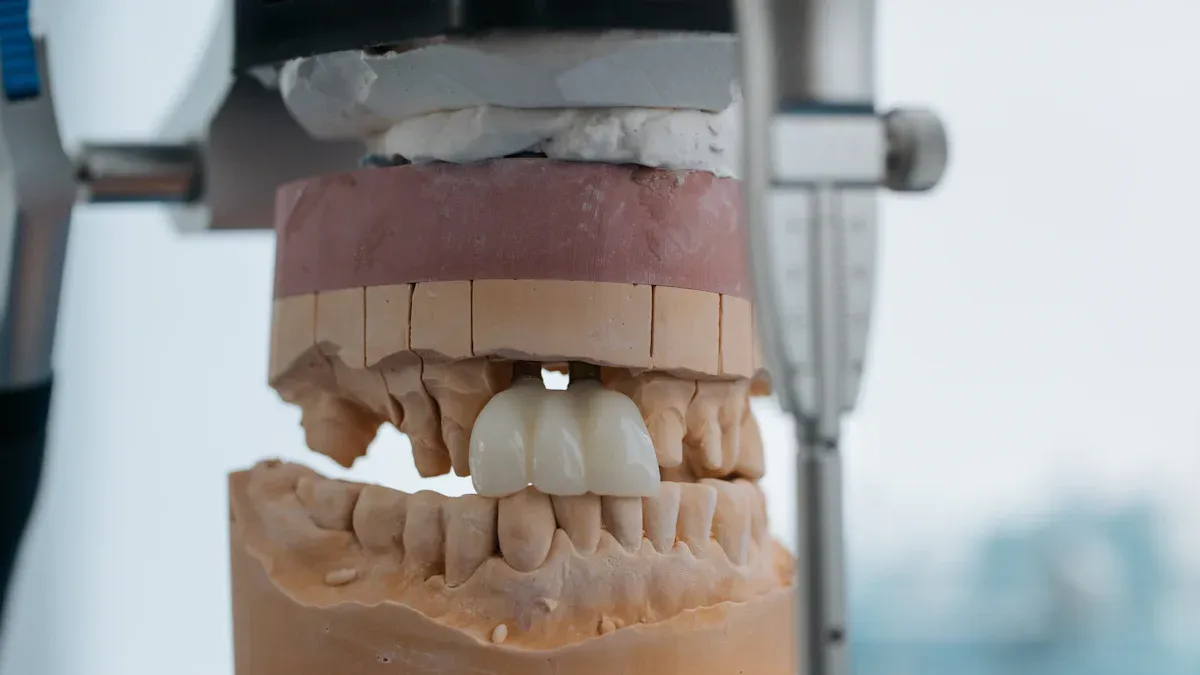

Orthodontic brackets serve as essential components in dental treatments aimed at correcting misaligned teeth and improving oral health. These small devices, bonded to the surface of teeth, act as anchors for orthodontic wires. By applying consistent pressure, they guide teeth into their desired positions over time. This process not only enhances the aesthetic appeal of a patient’s smile but also addresses functional issues such as bite alignment and jaw discomfort. Properly aligned teeth contribute to better oral hygiene by reducing the risk of cavities and gum disease, as they are easier to clean.

- Orthodontic brackets have evolved significantly since the early designs introduced by Edward Hartley Angle.

- Modern advancements, including self-ligating and ceramic brackets, offer both functional and aesthetic benefits.

- Technologies like 3D imaging and digital impressions have further improved the precision and comfort of orthodontic treatments.

Types of brackets used in orthodontics.

Orthodontic brackets come in various types, each designed to meet specific patient needs. These include:

| Bracket Type | Features and Advantages | Disadvantages |

|---|---|---|

| Ceramic | Aesthetic appeal, less visible than metal brackets | More brittle than metal |

| Self-ligating | Reduces friction, easier to clean, faster treatment times | Higher cost compared to traditional |

| Lingual | Hidden from view, aesthetic choice for adults | More complex to place and adjust |

| Metal | Cost-effective, durable, widely used in orthodontics | Less aesthetic appeal |

The choice of bracket depends on factors such as the patient’s age, treatment goals, and budget. For example, ceramic brackets are popular among adults seeking discreet options, while metal brackets remain a reliable choice for their durability and cost-effectiveness.

Why Quality Is Crucial

The impact of material quality on treatment success.

The quality of materials used in orthodontic brackets directly influences treatment outcomes. High-quality brackets ensure consistent performance by maintaining their structural integrity under the forces exerted during orthodontic adjustments. Materials like stainless steel and titanium are commonly used due to their strength and resistance to corrosion. Ceramic brackets, while aesthetically pleasing, require advanced manufacturing techniques to balance durability with visual appeal.

The design of orthodontic brackets often incorporates features like U-shaped bases and alpha–beta angle adjustments to enhance precision and adaptability. These innovations highlight the importance of material quality in achieving optimal results.

Risks associated with substandard brackets.

Substandard brackets pose significant risks to both patients and orthodontists. Poor-quality materials may corrode or fracture under stress, leading to treatment delays and additional costs. In some cases, they can cause adverse reactions, such as allergies or irritation of oral tissues. These issues not only compromise patient safety but also undermine the credibility of orthodontic bracket manufacturers. Ensuring compliance with industry standards mitigates these risks and fosters trust among dental professionals.

Material Standards in Orthodontic Bracket Manufacturing

Key Industry Standards

Overview of ANSI/ADA Standard No. 100

Orthodontic bracket manufacturers adhere to ANSI/ADA Standard No. 100 to ensure their products meet stringent quality benchmarks. This standard outlines requirements for orthodontic brackets and tubes, including functional dimensions, chemical ion release, and packaging specifications. It also provides detailed test methods to evaluate product performance. By following this standard, manufacturers guarantee that their brackets are safe, durable, and effective for clinical use.

| Standard | Description |

|---|---|

| ANSI/ADA Standard No. 100 | Specifies requirements for orthodontic brackets, including chemical safety and labeling. |

| ANSI/ADA Standard No. 100 E-BOOK | An electronic version available for purchase from the American Dental Association. |

ISO 27020:2019 and its significance

ISO 27020:2019, adopted as ANSI/ADA Standard No. 100, is a globally recognized guideline for orthodontic brackets. It emphasizes biocompatibility, corrosion resistance, and mechanical strength. Compliance with this standard ensures that brackets perform reliably under the challenging conditions of the oral environment. Manufacturers who meet ISO 27020:2019 demonstrate their commitment to producing high-quality orthodontic products.

Essential Material Requirements

Biocompatibility for patient safety

Biocompatibility is a critical requirement for orthodontic brackets. Materials must not cause adverse reactions or harm oral tissues. Titanium brackets, for instance, exhibit excellent biocompatibility and lower friction, which enhances tooth movement efficiency. Silver platinum-coated brackets also provide antibacterial properties, reducing the risk of biofilm development in patients with poor oral health.

Corrosion resistance and long-term durability

Orthodontic brackets must withstand the corrosive effects of saliva, fluoridated foods, and acidic dentifrices. Titanium and stainless steel brackets excel in corrosion resistance, maintaining their structural integrity over time. This durability ensures consistent performance throughout the treatment period, minimizing the risk of bracket failure.

Common Materials Used

Stainless steel, titanium, and ceramic

Orthodontic bracket manufacturers commonly use stainless steel, titanium, and ceramic due to their unique properties. Stainless steel offers affordability and durability, while titanium provides superior biocompatibility. Ceramic brackets, on the other hand, are valued for their aesthetic appeal.

Pros and cons of each material

| Type of Bracket | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel | Affordable, durable, corrosion-resistant | Less aesthetic, requires soldering |

| Titanium | Biocompatible, low friction, strong | Prone to plaque build-up and discoloration |

| Ceramic | Aesthetic, translucent, durable | Expensive, fragile, prone to staining |

Each material offers distinct benefits, allowing orthodontists to select the most suitable option based on patient needs and treatment goals.

Testing Methods Used by Orthodontic Bracket Manufacturers

Durability Testing

Stress and fatigue testing for mechanical strength.

Orthodontic brackets endure significant forces during treatment. Manufacturers conduct stress and fatigue tests to evaluate their mechanical strength. These tests simulate the repetitive forces brackets experience from chewing and orthodontic adjustments. By applying controlled stress levels, manufacturers assess the brackets’ ability to maintain structural integrity over time. This ensures that the brackets can withstand the demands of daily use without fracturing or deforming.

To validate durability, manufacturers follow strict protocols. For example, trial monitoring records adverse events from the bonding phase to the debonding stage. This process ensures compliance with safety standards and identifies potential weaknesses in the brackets. Ethics approval and data management practices further enhance the reliability of these tests, ensuring that the results align with Good Clinical Practice principles.

Evaluating resistance to wear and tear.

Wear and tear testing measures how brackets perform under prolonged exposure to friction and other mechanical forces. This includes evaluating the interaction between brackets and orthodontic wires, which can cause gradual material degradation. High-quality orthodontic bracket manufacturers use advanced equipment to replicate these conditions, ensuring their products remain functional throughout the treatment period. Consistent performance minimizes the risk of treatment delays and enhances patient satisfaction.

Biocompatibility Testing

Ensuring materials are safe for oral tissues.

Biocompatibility testing ensures that the materials used in orthodontic brackets do not harm oral tissues. Manufacturers test for cytotoxicity, which evaluates whether the materials release harmful substances. This step is crucial for patient safety, as brackets remain in contact with oral tissues for extended periods. Titanium and stainless steel brackets often excel in these tests due to their proven compatibility with human tissues.

Testing for potential allergic reactions.

Allergic reactions to bracket materials can cause discomfort and compromise treatment. Manufacturers conduct allergenicity tests to identify potential risks. These tests involve exposing materials to simulated oral conditions and monitoring for adverse reactions. By prioritizing biocompatibility, manufacturers ensure that their brackets meet the highest safety standards, reducing the likelihood of allergic responses.

Corrosion Resistance Testing

Simulating oral conditions to test for degradation.

The oral environment exposes brackets to saliva, food particles, and fluctuating pH levels. Corrosion resistance testing simulates these conditions to evaluate how brackets withstand degradation. Manufacturers immerse brackets in solutions that mimic saliva and acidic environments, observing their performance over time. This process ensures that the brackets maintain their structural integrity and do not release harmful ions into the mouth.

Importance of maintaining structural integrity.

Corrosion can weaken brackets, leading to fractures or treatment failures. By testing for corrosion resistance, manufacturers ensure that their products remain durable and reliable. This testing also helps orthodontists maintain confidence in the brackets’ performance, contributing to successful treatment outcomes.

Aesthetic Testing for Ceramic Brackets

Assessing color stability over time

Ceramic brackets are popular for their aesthetic appeal, but maintaining their color stability is essential for patient satisfaction. Manufacturers conduct rigorous tests to evaluate how these brackets retain their original shade over time. These tests often involve exposing the brackets to simulated oral conditions, such as varying temperatures and pH levels, to replicate the environment inside the mouth. By analyzing the results, manufacturers ensure that their products meet the highest standards of color stability.

Spectrophotometry is widely regarded as the gold standard for assessing color changes in ceramic brackets. This method measures subtle variations in color that may not be visible to the naked eye. However, it has limitations, such as its inability to account for subjective visual perceptions. To address this, manufacturers establish visual thresholds for perceptibility and acceptability, ensuring that any changes remain within acceptable limits.

| Evidence Type | Description |

|---|---|

| Discoloration Resistance | Most ceramic brackets resist discoloration, unlike elastomeric modules prone to degradation. |

| Assessment Methods | Spectrophotometry is the gold standard for evaluating color changes, despite its limitations. |

| Visual Thresholds | Parameters for perceptibility and acceptability are crucial for orthodontic products. |

Resistance to staining from food and beverages

Staining is a common concern for patients using ceramic brackets. Foods and beverages like coffee, tea, and red wine can cause discoloration over time. To address this, manufacturers test their brackets for resistance to staining by immersing them in staining agents under controlled conditions. These tests simulate real-world scenarios, allowing manufacturers to evaluate how well their products withstand exposure to common staining substances.

High-quality ceramic brackets often feature advanced coatings or surface treatments that enhance their resistance to staining. These innovations help maintain the brackets’ aesthetic appeal throughout the treatment period. By prioritizing stain resistance, manufacturers ensure that patients can enjoy the benefits of ceramic brackets without compromising on appearance.

Tip: Patients can further minimize staining by maintaining good oral hygiene and avoiding foods and drinks known to cause discoloration.

Importance of Compliance with Material Standards

Ensuring Patient Safety

How compliance reduces risks of adverse reactions.

Orthodontic bracket manufacturers prioritize compliance with material standards to minimize risks to patients. High-quality brackets undergo rigorous testing to ensure they do not release harmful substances or cause irritation to oral tissues. Materials like titanium and stainless steel are commonly used due to their proven biocompatibility. By adhering to established guidelines, manufacturers reduce the likelihood of allergic reactions and other adverse effects, ensuring a safer treatment experience for patients.

Note: Biocompatibility testing plays a critical role in identifying potential hazards before products reach the market. This proactive approach safeguards patient health and reinforces trust in orthodontic products.

The role of testing in identifying potential hazards.

Testing protocols help manufacturers detect and address potential hazards in orthodontic brackets. For example, corrosion resistance tests simulate oral conditions to evaluate how materials perform over time. These tests ensure that brackets maintain their structural integrity and do not degrade, which could lead to complications. By identifying weaknesses early, manufacturers can refine their products to meet stringent safety standards, ultimately enhancing patient outcomes.

Enhancing Product Reliability

How rigorous testing ensures consistent performance.

Consistent performance is essential for successful orthodontic treatments. Rigorous testing ensures that brackets can withstand the mechanical forces exerted during adjustments and daily activities like chewing. Stress and fatigue tests evaluate the durability of brackets, confirming their ability to maintain functionality throughout the treatment period. Reliable brackets improve placement techniques and enhance treatment efficiency, leading to better patient satisfaction.

The impact of reliable brackets on treatment outcomes.

Reliable brackets directly influence treatment success rates. Precision in bracket placement and standardized slot sizes contribute to optimal alignment and bite correction. Studies show that slot size variations, such as 0.018-inch versus 0.022-inch, can affect treatment duration and quality. Reliable brackets streamline these processes, improving overall outcomes for patients.

| Evidence Type | Description |

|---|---|

| Bracket Placement | Precision in placement ensures optimal alignment and bite correction. |

| Bracket Slot Size | Standardized sizes improve treatment efficiency and patient satisfaction. |

Building Trust with Dental Professionals

Why orthodontists prefer certified manufacturers.

Dental professionals increasingly prefer certified orthodontic bracket manufacturers due to their commitment to quality and innovation. Certified manufacturers align with the growing emphasis on patient-centered care by offering advanced solutions that enhance treatment outcomes. This trend reflects the adoption of cutting-edge technologies in dental clinics, which aim to improve patient experiences and satisfaction.

The role of certifications in establishing credibility.

Certifications serve as a mark of credibility for orthodontic bracket manufacturers. They demonstrate adherence to industry standards and a dedication to producing safe, reliable products. Healthcare providers often collaborate with certified manufacturers to integrate orthodontic treatments into their services. These partnerships highlight the importance of certifications in fostering trust and ensuring high-quality care.

Material standards and rigorous testing are the cornerstones of reliable orthodontic brackets. These practices ensure patient safety, enhance product durability, and improve treatment outcomes. By prioritizing compliance, orthodontic bracket manufacturers deliver products that meet clinical demands and foster trust among dental professionals.

| Type of Bracket | Advantages | Disadvantages |

|---|---|---|

| Stainless steel brackets | Affordable, durable, widely used | Not aesthetic, requires soldering |

| Ceramic brackets | Translucent, durable, aesthetically pleasing | Expensive, fragile, less ductile |

| Self-ligating brackets | Reduced friction, faster treatment times | Complex design, higher cost |

Historical trends in material performance further emphasize the importance of selecting high-quality brackets.

- Metal brackets remain a cost-effective and efficient choice for many orthodontists.

- Ceramic brackets cater to patients seeking aesthetic solutions.

- Self-ligating brackets offer advanced functionality with reduced chair-side assistance.

Patients and professionals alike should prioritize manufacturers who uphold these standards. This ensures optimal results, safety, and satisfaction throughout orthodontic treatment.

FAQ

What makes orthodontic brackets biocompatible?

Biocompatibility ensures that orthodontic brackets do not harm oral tissues or cause allergic reactions. Manufacturers use materials like titanium and stainless steel, which are proven safe for prolonged contact with the human body. Rigorous biocompatibility testing further guarantees patient safety.

How do manufacturers test the durability of orthodontic brackets?

Manufacturers conduct stress and fatigue tests to evaluate the mechanical strength of brackets. These tests simulate chewing forces and orthodontic adjustments, ensuring the brackets maintain their structural integrity throughout treatment. This process ensures reliable performance under daily use.

Why is corrosion resistance important in orthodontic brackets?

Corrosion resistance prevents brackets from degrading in the oral environment, which contains saliva, food particles, and fluctuating pH levels. Materials like stainless steel and titanium resist corrosion, ensuring long-term durability and preventing harmful ion release into the mouth.

What are the benefits of ceramic brackets?

Ceramic brackets offer aesthetic advantages due to their translucent appearance, blending with natural teeth. They resist staining when properly manufactured and tested. These brackets are ideal for patients seeking discreet orthodontic solutions without compromising on performance.

How do certifications impact orthodontic bracket quality?

Certifications, such as compliance with ISO 27020:2019, demonstrate a manufacturer’s commitment to quality and safety. Certified manufacturers adhere to stringent industry standards, ensuring their products meet clinical requirements. This builds trust among dental professionals and patients.

Post time: Mar-23-2025