Choosing reliable orthodontic bracket suppliers is essential for ensuring effective orthodontic treatment. Poor-quality brackets can lead to significant complications, such as discomfort, inefficiency in correcting misalignments, and a negative impact on oral health-related quality of life. For instance, studies show that patients treated with brackets reported higher OHIP-14 scores, with one-month post-treatment scores reaching 33.98 ± 6.81, compared to 27.33 ± 6.83 for aligners. This highlights the critical role of quality in patient satisfaction and outcomes. A comprehensive quality checklist can guide dental professionals in selecting suppliers who prioritize safety, durability, and consistent performance.

Key Takeaways

- Pick suppliers with ISO 13485 and FDA approvals for safe brackets.

- Check if the supplier can make enough brackets on time.

- Find suppliers using advanced tools for accurate and comfy brackets.

- Read customer reviews to spot trusted suppliers with good service.

- Choose suppliers known for awards and ties with dental groups.

- Ask for clear pricing details to avoid surprise costs.

- Go for suppliers with great support after buying their products.

- Make sure bracket materials are safe and comfy for patients.

Certifications and Standards

Regulatory Compliance

ISO Certifications

ISO certifications are critical benchmarks for evaluating the reliability of orthodontic bracket suppliers. ISO 13485, a globally recognized standard, ensures that suppliers maintain robust quality management systems tailored to medical device manufacturing. This certification guarantees that products meet stringent safety and performance requirements. Suppliers adhering to ISO 13485 demonstrate their commitment to delivering high-quality orthodontic brackets that comply with international regulations.

Additionally, compliance with ISO standards fosters consistency in production processes. It minimizes the risk of defects, ensuring that orthodontic brackets perform as intended during treatment. Dental professionals should prioritize suppliers with ISO certifications to ensure patient safety and satisfaction.

FDA Compliance

For suppliers targeting the U.S. market, FDA approval is non-negotiable. This certification signifies that orthodontic brackets meet rigorous safety and effectiveness standards. The FDA mandates continuous monitoring, adverse event reporting, and periodic safety updates to maintain compliance. Suppliers must also conduct post-market clinical follow-ups to assess long-term product performance.

A systematic approach to regulatory compliance, including risk management and corrective actions, ensures that suppliers can address potential issues promptly. Orthodontic bracket suppliers with FDA approval provide dental professionals with confidence in the quality and reliability of their products.

Regional and Industry Standards

CE Marking

CE marking is essential for suppliers aiming to access the European market. This certification indicates that orthodontic brackets comply with EU safety, health, and environmental protection standards. It also facilitates seamless market entry and ensures that products meet the expectations of European dental professionals.

Suppliers with CE marking demonstrate their adherence to stringent regulatory requirements, enhancing their credibility and marketability. Dental professionals should verify this certification when evaluating potential suppliers.

Other Regional Certifications

In addition to ISO and CE certifications, suppliers may require region-specific approvals to operate in certain markets. For instance:

- CFDA certification ensures compliance with Chinese safety and quality standards.

- TGA and ANVISA approvals validate adherence to Australian and Brazilian regulations, respectively.

- Compliance with international standards like GRI and ISO 26000 promotes supplier accountability and transparency.

Regular audits and risk assessments, as recommended by regulatory bodies like the FDA, further ensure that suppliers maintain high-quality standards. Non-compliance can result in legal penalties and reputational damage, underscoring the importance of selecting certified suppliers.

Manufacturing Capabilities

Production Capacity

Scalability for Demand

Reliable orthodontic bracket suppliers must demonstrate the ability to scale production to meet varying levels of demand. This scalability ensures that dental professionals can access the required quantity of brackets without delays, even during peak periods. Suppliers with advanced production facilities and automated systems can adjust their output efficiently. For instance, factories equipped with multiple production lines can increase capacity without compromising quality.

Scalability also reflects a supplier’s preparedness for market fluctuations. Suppliers who invest in flexible manufacturing processes can adapt to sudden increases in demand, ensuring uninterrupted supply chains. Dental professionals should evaluate a supplier’s production capacity to avoid shortages that could disrupt patient care.

Consistency in Quality

Consistency in quality is a hallmark of dependable orthodontic bracket suppliers. High-quality brackets must meet the same standards across every batch, ensuring uniform performance during treatment. Suppliers achieve this consistency through stringent quality control measures and standardized manufacturing protocols.

Automated production lines and advanced testing equipment play a crucial role in maintaining quality. These technologies minimize human error and ensure that each bracket meets predefined specifications. Dental professionals should prioritize suppliers who emphasize consistent quality to enhance treatment outcomes and patient satisfaction.

Advanced Technology

Precision Manufacturing

Precision manufacturing is essential for producing orthodontic brackets that fit accurately and function effectively. Suppliers utilizing cutting-edge technology, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), can achieve unparalleled precision. These tools enable the creation of brackets with exact dimensions, ensuring optimal alignment and comfort for patients.

Additionally, precision manufacturing reduces the likelihood of defects, enhancing the reliability of the brackets. Suppliers who invest in advanced machinery and skilled technicians demonstrate their commitment to delivering superior products. Dental professionals should assess a supplier’s manufacturing capabilities to ensure precision in every bracket.

Innovative Designs

Innovative designs set leading orthodontic bracket suppliers apart from their competitors. Modern brackets incorporate features that improve functionality and patient comfort, such as low-profile designs and rounded edges. These advancements reduce irritation and enhance the overall treatment experience.

Suppliers who prioritize innovation often collaborate with dental professionals to develop products that address specific needs. For example, self-ligating brackets and aesthetic options like ceramic brackets reflect the industry’s focus on patient-centric solutions. Dental professionals should seek suppliers who embrace innovation to stay ahead in the evolving field of orthodontics.

Product Quality and Materials

Types of Brackets

Metal Brackets

Metal brackets remain a popular choice among orthodontic bracket suppliers due to their durability and cost-effectiveness. These brackets, typically made from stainless steel, offer high tensile strength and resistance to corrosion. Their affordability makes them an ideal option for budget-conscious patients. Furthermore, advancements in design have led to smaller, more comfortable metal brackets that reduce irritation and improve patient compliance.

Orthodontic professionals often recommend metal brackets for their reliability in addressing complex dental misalignments. The use of nickel titanium wires with these brackets minimizes the need for frequent adjustments, reducing chairside visits and enhancing treatment efficiency.

Ceramic Brackets

Ceramic brackets cater to patients who prioritize aesthetics during orthodontic treatment. These brackets, crafted from translucent or tooth-colored materials, blend seamlessly with natural teeth, making them less noticeable. While ceramic brackets are slightly more expensive than their metal counterparts, their visual appeal justifies the cost for many patients.

In addition to their aesthetic advantages, ceramic brackets maintain sufficient strength to handle moderate orthodontic corrections. However, they require careful handling to prevent chipping or cracking. Orthodontic bracket suppliers offering ceramic options often emphasize their biocompatibility and smooth surface finish, which contribute to patient comfort and satisfaction.

Material Safety

Biocompatibility

Biocompatibility is a critical factor in evaluating the safety of orthodontic brackets. Materials used in brackets must not cause adverse reactions, such as allergies or tissue irritation. Suppliers adhering to certifications like ISO 13485:2016 and FDA regulations ensure that their products meet stringent biocompatibility standards. Advanced coatings and surface treatments further enhance the safety of these materials by reducing the risk of corrosion and improving their compatibility with oral tissues.

Long-term clinical studies play a vital role in assessing the biocompatibility of orthodontic materials. Data collected from diverse patient populations helps identify potential complications, such as allergic reactions or material degradation. These insights drive continuous improvements in bracket design and material selection, ensuring better outcomes for patients.

Durability Testing

Durability testing ensures that orthodontic brackets can withstand the mechanical stresses of daily use. Rigorous testing protocols, including wear and corrosion resistance evaluations, validate the long-term performance of these medical devices. Suppliers who invest in advanced testing equipment can identify defects early, ensuring that only high-quality products reach the market.

Orthodontic bracket suppliers must comply with international standards, such as ISO 27020:2019, to guarantee product reliability. This standard emphasizes the importance of strict quality controls throughout the manufacturing process. By adhering to these guidelines, suppliers can produce brackets that maintain their structural integrity and functionality over time.

Tip: Dental professionals should prioritize suppliers who conduct regular evaluations and adhere to certifications like EU MDR and FDA approval. These measures ensure the safety and durability of orthodontic brackets, enhancing patient satisfaction and treatment success.

Assessing Supplier Reputation

Customer Feedback

Verified Reviews

Customer feedback serves as a critical indicator of a supplier’s reliability. Verified reviews, often found on trusted platforms or through direct testimonials, provide insights into the quality and performance of orthodontic brackets. Dental professionals should prioritize suppliers with consistently positive reviews that highlight product durability, precision, and patient satisfaction. Verified reviews also help identify suppliers who excel in customer service, ensuring smooth communication and prompt issue resolution.

Identifying Red Flags

Negative feedback or recurring complaints can signal potential issues with a supplier. Common red flags include delayed deliveries, inconsistent product quality, or lack of responsiveness to customer concerns. Dental professionals should carefully analyze patterns in reviews to avoid suppliers with a history of unresolved problems. Additionally, suppliers with limited or no customer feedback may lack the transparency needed to establish trust.

Industry Recognition

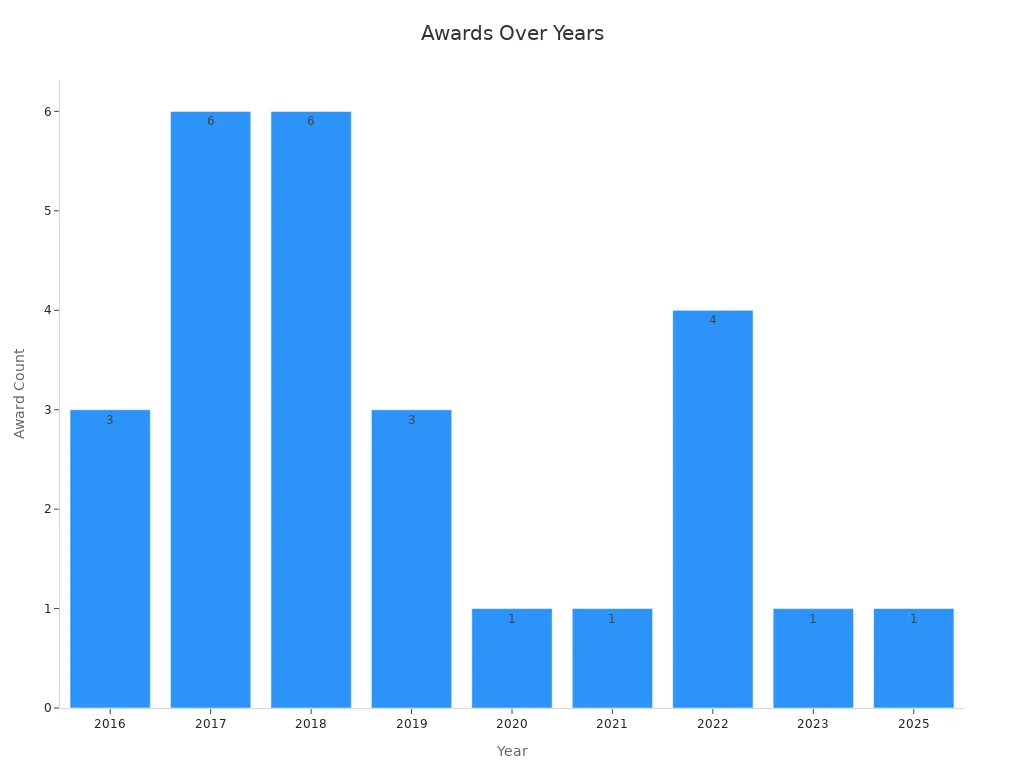

Awards and Certifications

Industry recognition through awards and certifications underscores a supplier’s commitment to excellence. Prestigious accolades validate their adherence to high standards in manufacturing, innovation, and customer service. For example, suppliers recognized by organizations like the CMO Leadership Awards or the Pharma Industry Awards demonstrate their credibility and expertise.

| Date | Award Name | Category/Recognition |

|---|---|---|

| 12 May 2023 | Made in Northern Ireland Awards 2023 | Manufacturing Apprenticeship/Training Scheme Award |

| 11 April 2025 | ABC Council Business Awards 2022 | Best Apprentice Employer of the Year |

| 13 May 2022 | Made in Northern Ireland Award 2022 | Winner of Medical, Life Sciences and Healthcare category |

| 26 May 2022 | Belfast Telegraph Business Awards | Best Large Company and Best Overall Business of the Year |

These awards highlight the supplier’s dedication to quality and innovation, making them a reliable choice for orthodontic bracket suppliers.

Partnerships with Dental Organizations

Collaborations with reputable dental organizations further enhance a supplier’s reputation. Partnerships with entities like the American Association of Orthodontists (AAO) or the European Orthodontic Society (EOS) indicate alignment with industry standards and best practices. Such affiliations also reflect the supplier’s active involvement in advancing orthodontic care, fostering trust among dental professionals.

Longevity and Stability

Years in Business

A supplier’s longevity in the market often correlates with their reliability and expertise. Companies with a long-standing presence have likely weathered industry challenges and adapted to evolving standards. Their experience enables them to deliver consistent quality and address customer needs effectively. Dental professionals should consider suppliers with a proven track record to ensure dependable partnerships.

Financial Reliability

Financial stability is another crucial factor when assessing supplier reputation. Suppliers with strong financial health can invest in advanced manufacturing technologies, maintain robust supply chains, and offer competitive pricing. Financially reliable companies are also better equipped to handle market fluctuations, ensuring uninterrupted service. Evaluating financial reports or seeking third-party assessments can provide valuable insights into a supplier’s stability.

Tip: Dental professionals should prioritize orthodontic bracket suppliers with a combination of positive customer feedback, industry recognition, and financial stability to ensure long-term reliability.

Quality Management and Compliance

Quality Assurance

Testing Protocols

Orthodontic bracket suppliers must implement rigorous testing protocols to ensure product reliability and safety. These protocols validate the performance of brackets under various conditions, such as mechanical stress, corrosion, and wear. Suppliers often collaborate with accredited third-party laboratories to conduct these tests. These laboratories provide validation data for testing methods, calibration records, and proficiency testing results.

Additionally, suppliers must maintain detailed documentation on batch production and quality assurance processes. This includes records of study protocols, data integrity, and regulatory submissions. Such documentation ensures transparency and compliance with global standards like Good Clinical Practice (GCP) and Good Laboratory Practice (GLP). By adhering to these protocols, suppliers demonstrate their commitment to delivering high-quality orthodontic brackets.

Documentation Standards

Comprehensive documentation is a cornerstone of effective quality assurance. Suppliers must provide detailed records of calibration standards, traceability to national benchmarks, and maintenance logs for testing equipment. These documents ensure that all processes align with regulatory requirements and industry best practices.

Service providers must also offer references, case studies, and documentation of past regulatory submissions. This information helps dental professionals assess the supplier’s expertise and reliability. Suppliers who prioritize meticulous documentation enhance their credibility and foster trust among their clients.

| Metric | Description |

|---|---|

| On-Time Delivery Performance | Measures the reliability of a supplier in delivering goods as scheduled, crucial for manufacturing flow. |

| Defect Rates | Indicates the quality of goods received, calculated as the ratio of defective units to total units. |

| Supplier Audit Findings | Results from evaluations assessing adherence to quality standards, revealing non-conformities and risks. |

Risk Management

Handling Recalls

Effective risk management includes a robust system for handling product recalls. Suppliers must have clear protocols for identifying defective products, notifying affected parties, and removing faulty items from the market. These protocols minimize the impact of recalls on dental professionals and patients.

Suppliers should also conduct root cause analyses to prevent future issues. This involves identifying the underlying reasons for defects and implementing corrective actions. By addressing these problems proactively, suppliers can maintain their reputation and ensure the safety of their products.

Supply Chain Transparency

Transparency in the supply chain is essential for mitigating risks and ensuring product quality. Suppliers must provide detailed information about their sourcing practices, manufacturing processes, and distribution networks. This transparency allows dental professionals to verify that all materials and components meet regulatory standards.

Regular audits and risk assessments further enhance supply chain reliability. Suppliers who prioritize transparency build stronger relationships with their clients and demonstrate their commitment to ethical practices. Dental professionals should seek suppliers who maintain open communication and provide comprehensive supply chain documentation.

Tip: Choosing suppliers with transparent supply chains and effective recall protocols ensures consistent quality and minimizes risks in orthodontic treatments.

Pricing and Support Services

Pricing Transparency

Avoiding Hidden Costs

Transparent pricing is a cornerstone of reliable orthodontic bracket suppliers. Dental professionals should request an itemized breakdown of costs, including unit prices, shipping fees, taxes, and additional services. This approach helps identify hidden charges that could impact profit margins. Suppliers who provide clear and upfront pricing foster trust and ensure smoother financial transactions.

Tip: Avoid suppliers who hesitate to disclose detailed pricing information, as this could indicate potential reliability issues.

Comparing Supplier Prices

Comparing quotes from multiple suppliers is essential for evaluating market rates and ensuring competitiveness. While the lowest bid may seem appealing, it often compromises quality. Dental professionals should balance cost-effectiveness with product reliability. Transparent financial relationships with suppliers encourage timely deliveries and consistent service.

- Key considerations when comparing prices:

- Total cost, including additional fees.

- Quality assurance measures offered by the supplier.

- Supplier reputation and customer feedback.

Customer Support

Technical Assistance

Technical assistance plays a vital role in ensuring the effective use of orthodontic brackets. Reliable suppliers provide comprehensive support, including guidance on product usage, troubleshooting, and training for dental professionals. This assistance minimizes errors during treatment and enhances patient outcomes.

Suppliers with dedicated technical support teams demonstrate their commitment to customer satisfaction. Prompt responses to inquiries and proactive problem-solving build trust and strengthen professional relationships.

Post-Sale Services

Post-sale services significantly influence customer satisfaction and loyalty. Suppliers who prioritize after-sales support often see higher retention rates and positive word-of-mouth marketing. These services may include warranty coverage, replacement policies, and ongoing communication to address customer concerns.

- Benefits of robust post-sale services:

- Improved customer experiences.

- Increased likelihood of repeat business.

- Enhanced brand reputation through positive feedback.

Note: Dental professionals should evaluate a supplier’s post-sale support policies before establishing long-term partnerships.

Customization Options

Tailored Solutions

Suppliers offering tailored solutions cater to the unique needs of dental professionals and their patients. Customization may include specialized bracket designs, personalized packaging, or unique product features. These options allow orthodontists to provide more effective and patient-centric treatments.

Late-stage personalization, such as hybrid printing for customized packaging, enables suppliers to adapt to market trends and consumer preferences. This flexibility fosters deeper connections with clients and enhances brand loyalty.

Flexible Packaging

Packaging serves as the first point of interaction between the product and the customer. Visually appealing and functional packaging creates a positive impression and reinforces brand identity. Suppliers who invest in innovative packaging solutions stand out in a competitive market.

- Advantages of flexible packaging:

- Enhanced customer satisfaction through thoughtful design.

- Differentiation from competitors by showcasing creativity.

- Increased trust through transparent and honest labeling.

- Studies show that 72% of American consumers consider packaging design a key factor in purchase decisions.

- Additionally, 74% of shoppers trust brands more when product labeling is clear and transparent.

Tip: Dental professionals should seek suppliers who prioritize customization and flexible packaging to improve client experiences and build long-term relationships.

Evaluating orthodontic bracket suppliers with a comprehensive checklist ensures better treatment outcomes and minimizes risks. High-quality materials improve results for 75% of orthodontists, while poor supplier choices can lead to financial losses ranging from $10,000 to $50,000 per product failure.

| Evidence Type | Statistic |

|---|---|

| Impact of High-Quality Materials | 75% of orthodontists report improved treatment results |

| Financial Liabilities from Poor Selection | Ranges from $10,000 to $50,000 per product failure |

Certifications, reputation metrics, and customer support play pivotal roles in building reliable partnerships:

- Certifications confirm compliance with safety and quality standards.

- Reputation Metrics reflect supplier reliability through positive reviews and testimonials.

- Customer Support ensures quick issue resolution, fostering trust and long-term collaboration.

Dental professionals should apply this checklist to make informed decisions, ensuring consistent quality and patient satisfaction.

FAQ

What certifications should orthodontic bracket suppliers have?

Suppliers should hold ISO 13485 certification, FDA approval (for U.S. markets), and CE marking (for Europe). These certifications ensure compliance with international safety and quality standards, guaranteeing reliable and effective orthodontic products.

How can dental professionals verify a supplier’s reputation?

Professionals can review verified customer feedback, industry awards, and partnerships with reputable dental organizations. Longevity in the market and financial stability also indicate a supplier’s reliability and expertise.

Why is biocompatibility important in orthodontic brackets?

Biocompatibility ensures that materials used in brackets do not cause allergic reactions or tissue irritation. This factor is critical for patient safety and comfort during orthodontic treatment.

What role does advanced technology play in manufacturing brackets?

Advanced technology, such as CAD/CAM systems, ensures precision manufacturing. This results in brackets with accurate dimensions, enhancing their functionality and patient comfort during treatment.

How can suppliers demonstrate transparency in pricing?

Suppliers should provide itemized cost breakdowns, including unit prices, shipping fees, and taxes. Transparent pricing fosters trust and helps dental professionals avoid unexpected expenses.

What are the benefits of flexible packaging options?

Flexible packaging enhances customer satisfaction by offering visually appealing and functional designs. It also allows suppliers to adapt to specific branding needs, improving product presentation and differentiation.

How do suppliers handle product recalls?

Reliable suppliers implement clear recall protocols, including identifying defective products, notifying customers, and removing faulty items. They also conduct root cause analyses to prevent future issues.

Why is post-sale support essential for orthodontic bracket suppliers?

Post-sale support ensures customer satisfaction through warranty coverage, replacement policies, and ongoing communication. This service fosters trust and encourages long-term partnerships with dental professionals.

Tip: Dental professionals should use this FAQ as a quick reference when evaluating orthodontic bracket suppliers to ensure informed decision-making.

Post time: Apr-11-2025